Waste Tyre/Plastic/Rubber Prolysis Plant

- Waste tire pyrolysis plant is one of the main ways of tire recycling at present. Waste tires go through a series of pyrolysis recycling processes in this equipment, and finally turn into gas, oil, carbon black and iron wire.

- Dingshuo Machinery provides site design and product customization, and we are 100% large and trustworthy manufacturer, welcome to visit our factory.

- Contact us:Tel/Whatsapp:+86-15516907866 E-Mail:sgmahine12@163.com

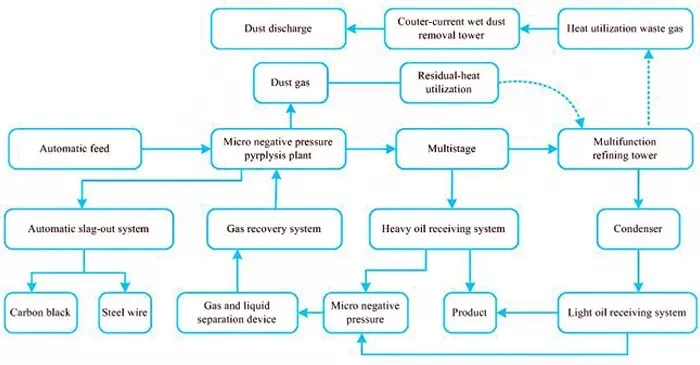

Working process of tire fuel oil plant:

First, the raw materials are put into the reactor, and then seal the feeding in door, later start the machine and the reactor will be rotating and heated by coal, natural gas, wood or electricity. When the temperature reaches the degree of 250 to 280, we will get the crude oil, the oil steam will be continuous produced until the temperature reaches 350-460°C; oil steam will flow through oil gas separator, light component will enter the condensers and meanwhile the heavy oil will be discharged automatically into in heavy oil tank. The liquefied part will be condensed as crude oil, and the part which cannot be liquefied will be transferred by the water seal back to the burning chamber to be reused as heating material

As a result of pyrolysis of waste tyres one obtains:

*Oil(45% to 50%)

The main oil product produced by our recycling application is the fuel oil that is wide used for industrial and commercial purposes. The oil has 45% to 50% of the amount of recycled scrap tyres, which will be carried with licensed tanker trucks.

*CARBON BLACK (30% to 35%)

Carbon Black is the main product recycled by Pyrolysis technology. The amount of recycled carbon black is 30% to 35% of the total amount of scrap tyres recycled in the system.

Carbon black produced by Pyrolysis process (CBp) is more economical compared to carbon black produced primarily from petroleum and is more price-efficient to be used as an ingredient in the industries listed;

*STEEL WIRE (10% to 15%)

Tyres contain steel wires and the amount range of 10% to 15% of the total tyre wastage

*GAS (5% to 8%)

Non-Condensable gases arise during the pyrolysis process.

Waste Tire Pyrolysis Plant Equipment Features:

-

Equipment: Adopting one of the most advanced equipment in cracking industry with high degree of automation, high product generation rate and quality, fast production speed, strong safety performance and easy operation.

-

One-piece main furnace shell: one-piece design, good heat preservation effect, and easy to transport and install.

-

The two ends of the main pyrolysis furnace are increased with one-piece lathe-machined bracket, which makes the equipment run more smoothly, reduces the vibration effect at the outlet to a minimum, effectively reduces the problem of oil and gas leakage, and reduces the failure rate of sealing part.

-

Enlarged support wheel: This set of equipment adopts the latest self-adjusting drag wheel, which can effectively decompose the stress point of supporting the furnace body and make the cracking equipment run more smoothly, safely and reliably.

-

Exclusive R&D and design of main furnace anti-sticking wall device, which can effectively reduce the problem of material sticking to the wall in the production process. The device can reduce the cleaning frequency, shorten the maintenance time and cost of the equipment, increase the production time and prolong the service life of the main furnace.

-

Enhanced sealing design, effectively improve equipment safety and environmental protection.

-

Tank cooling system: one-piece box design, easy to transport and install. The cooling pipe is placed in the water and the cooling tower works together to circulate the cooling of condensable oil and gas, with good cooling effect, high oil yield, good oil quality and long service life. The elbows at both ends are easy to dismantle and easy to clean and maintain.

-

Gas recovery system: non-condensable gas can be returned to the furnace through the two-stage safety water seal to fully combust, not only to save combustion 8 burn, and to avoid causing secondary pollution.

-

Safety: fully humane design and automated explosion-proof system control, effectively reducing the incidence of flash explosions.

-

Scope of application: such as waste tyres, waste plastics, waste rubber, domestic waste, kitchen waste, waste paint residue, oil sludge sludge, oilfield waste, electroplating sludge and other organic solid waste.

Tyre Pyrolysis Machine Product Parameters:

| Product Name | Tyre Pyrolysis Machine | |||

| Capacity | 2TPD, 5TPD ,6TPD 8TPD ,10TPD,12TPD,15TPD | |||

| Reactor Materials | Q345R,Alloy Steel,Stainless Steel | |||

| Reactor Thinckness | 16.45mm, 18.50mm | |||

| Total weight | 30-40ton (Varies by Design and Capacity) | |||

| Working power | 15-35KW(Varies by Design and Capacity) | |||

| Labor Qty Require | 2-4 Person for per set machine,more machine ,fewer labors | |||

| Processing Time | feeding 2Hours,processing 8-9 hours,Carbon black and steel wire Discharging 1.5hours( Take 12ton Capacity for example) | |||

| Application Materials | Waste tyre,Waste rubber,Waste plastic ,waste oil sludge ,waste Aluminum foil,Waste cable ,waste leather ,waste Acrylic(PMMA), ect..... | |||

| Heating fuel | pyrolysis oil ,Natural gas ,Electricity,Coal ,Firewood ect... | |||

Get A Quote

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.