Fully Automatic Lithium Battery Recycling Machine Equipment

- Copper and aluminum recovery (by weight): ≥ 98%

- Positive and negative material recovery (by weight%): ≥ 99%

- Iron recovery (by weight): ≥ 99%

- Applied materials: laptop battery, cellphone lithium battery, pouch cell, cylindrical battery, lithium cell, li-ion battery, lithium-ion batteryetc, etc.

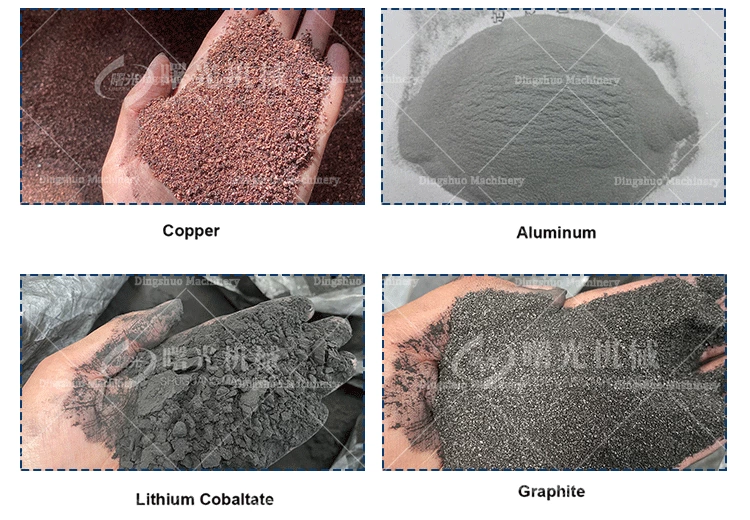

- Finished product: aluminum, copper, lithium, lithium cobalt oxide, anode materialis graphite.

- Dingshuo Machinery provides site design and product customization, and we are 100% large and trustworthy manufacturer, welcome to visit our factory.

- Contact us:Tel/Whatsapp:+86-15516907866 E-Mail:sgmahine12@163.com

Lithium Battery Recycling Machine System Development Prospects:

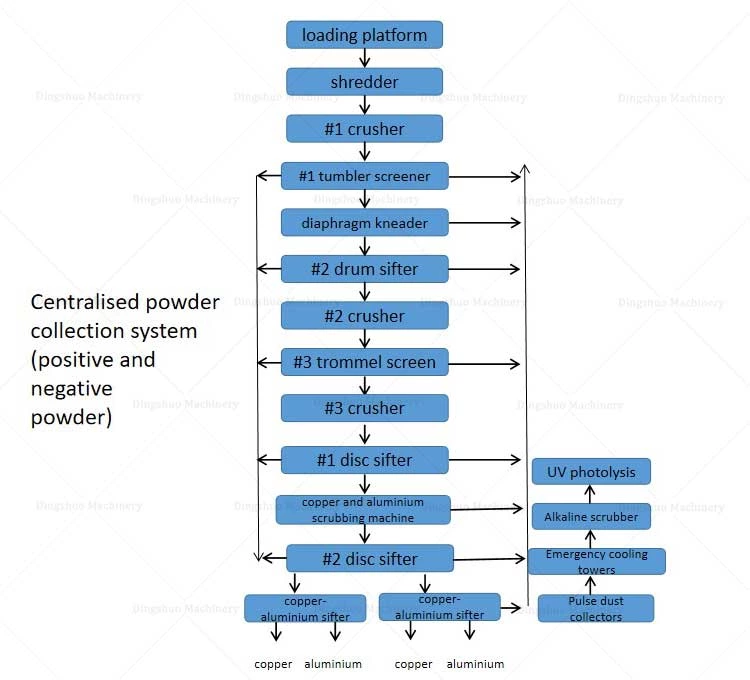

Lithium battery crushing and sorting Equipment separates and regenerates waste lithium batteries by separating them into the raw materials we need.Lithium battery recycling and processing equipment crushes and crushes the raw materials with multi-knife crushing,and separates and processes them by airflow sorting facilities,with pulse dust removal facilities to collect the dust generated during the separation process and subsequent processes.Form the whole life cycle of the battery green, high quality closed-circuit recycling system, lithium battery crushing and recycling equipment is mainly used in the end-of-life lithium battery positive and negative pieces of aluminum berth, copper berth and positive and negative materials for separation and processing, in order to recycle, with the industry development environment optimization, lithium battery resource utilization of the development prospects are considerable.

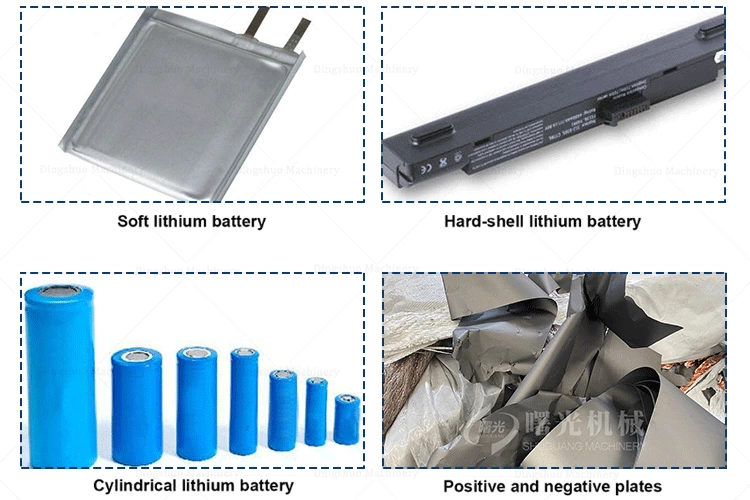

Battery Recycling Machine Applied Materials:

The final products of this plant is Graphite powder, Cobalt acid lithium,Aluminum and copper.

Battery Recycling Plant Finished product:

The lithium battery recycling production line is used for dismantling andrecycling the Soft pack-age battery, cellphone battery, Shell battery,Cylindrical battery etc. Different types of lithium bat-teries have different recycling procedures. Please contact us for detailed configuration.

The copper (up to 35%) in used lithium batteries is a widely used and important raw material for production, and the carbon powder adhered to it can be used as an additive in plastics and rubber. Therefore, the effective separation of the constituent materials of waste lithium battery negative electrodes is a driving force in maximising the resourcefulness of waste lithium batteries and eliminating their corresponding environmental impact. Commonly used methods for waste lithium battery recycling include hydrometallurgy, pyrometallurgy and mechanical-physical methods. Compared to wet and pyro-metallurgical methods, the mechanical-physical method does not require the use of chemical reagents and consumes less energy, making it an environmentally friendly and more efficient method.

Advantages Of The Waste Lithium Battery Electrode Processing Equipment:

1. Lithium battery recycling plant mainly adopts physical recycling method, which has the characteristics of green and low carbon, energy saving and environmental protection, and no secondary pollution.

2. Taking economic and environmental benefits into account, both valuable components can be utilized and harmful components can be treated innocuously.

3. Lithium battery recycling machine was automatic, high recovery efficiency, strong processing capacity, waste lithium battery valuable components recovery rate of more than 98%.

Lithium-Ion Battery Recycling Plant Craft:

lithium-ion battery recycling plant product parameters:

| Model | Power(kw) | Weight(kg) | Size(m) | Capacity(kg/h) |

| 500 | 95 | 20000 | 25*6*5 | 400-500 |

| 1000 | 195 | 40000 | 35*8*8 | 800-1000 |

*Note: Due to the wide variety of materials, the output should be based on the characteristics of the material. Depending on the customer's site, material and budget, we can offer customised solutions.

Get A Quote

If you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.